Explosion proof lift trucks must adhere to guidelines and regulations to maintain compliance. From the components that make up the machine to the hazardous areas they are approved to operate in, it is important to know these regulations for explosion proof trucks.

An EX forklift is a specific model which has been designed, constructed, assembled, and certified by a certified testing lab (UL, Factory Mutual, etc.) such that its usage is permitted in atmospheres containing specifically named flammable vapors, dusts, or fibers.

These certified lift trucks are meant to avoid property damage, but more importantly, this equipment saves lives. It is critical to have an understanding of these vehicles and their regulations to maintain compliance for safety.

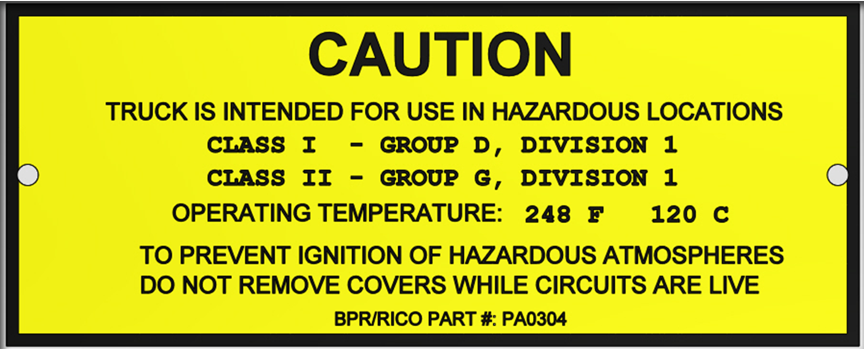

In the UL 583 standard, you will find that Explosion Proof trucks must have markings that are clearly visible calling out the hazardous classification of the vehicle. This is essential information about the vehicle. Our experts are here to detail these markings for you.

Type Designation

UL 583 standard states that EX trucks “shall be marked with the type designation, applied to each side of the vehicle in a prominent location.” RICO applies this EX type designation to the left, rear and right sides of the truck, as there is not a prominent location to the front of the units.

These markings are fastened to a permanent location. RICO does not apply these on removable parts such as covers.

The type designation (seen below) must have a 5” width and a yellow background with black letters and black outline.

Class and Group of Hazardous Location(s)

The Class and Group for which the truck is approved and intended for use also must be present. All RICO Explosion Proof trucks are approved and labeled to operate in the following hazardous areas:

- Class I, Division 1 & 2, Group D

- Class II, Division 1 & 2, Group G

Maximum Operating Temperature

The above is an example of the marking you will find on a RICO EX lift truck listing both the Classification and the Operating Temperature.

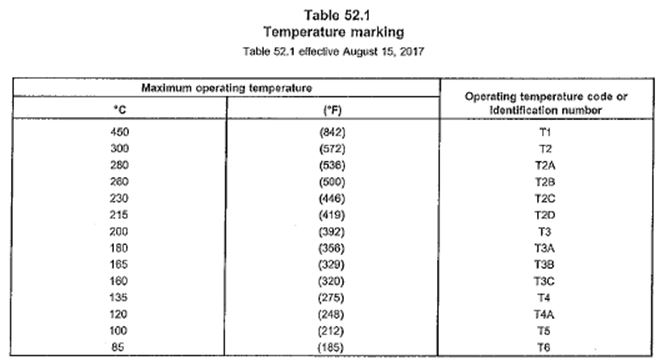

The maximum external operating temperature, or operating temperature class (T-Code), as indicated in the below table from UL 583 must be present. It shall be properly identified, for example, “Operating Temperature” or “Operating Temperature Code”.

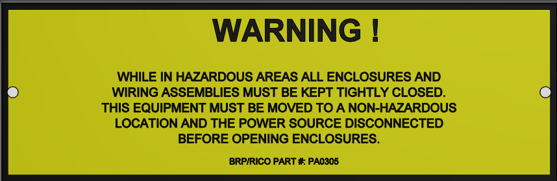

Electrical Wiring and Enclosure Assembly Statement

A statement calling attention to the necessity for keeping enclosures of electrical parts and wiring tightly assembled while in hazardous areas is also required.

It is very important to remember to perform all repairs and maintenance outside of the designated hazardous area, including charging the explosion proof vehicle.

If you are interested in learning more about EX enclosures, we detailed this protection method in a previous blog.

Other Information

Other information that needs to be listed, which can be found on all RICO equipment data tags:

- Name or trademark of the manufacturer

- Catalog designation or equivalent identification

- Normal voltage rating of the battery

- The truck gradeability

- A schematic or pictorial circuit-wiring diagram

- This diagram is provided in your equipment manual

EX standards and regulations can sometime be difficult to understand. We’re here to help! It is important to remember that only EX trained technicians should perform maintenance and repairs to maintain proper compliance for this equipment.

For additional training or information on these ratings or to request a quote, we encourage you to contact us to speak with one of our experts!