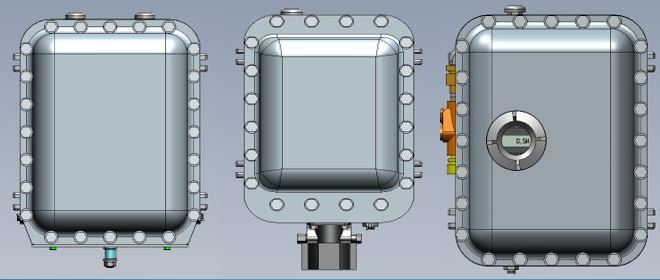

EX Enclosures are an integral part of the explosion proof lift truck design. But why? What do these enclosures do?

If you have read our previous blogs, you know that a certified EX rated lift truck is a special model which has been designed, constructed, assembled and certified by a certified testing lab (UL, Factory Mutual, etc.) such that its usage is permitted in atmospheres containing specifically named flammable vapors, dusts, or fibers.

An explosion proof enclosure is just one protection method that makes up a certified EX forklift build system, and our experts are here to explain what it is and what it does.

An EX enclosure is a case, or housing, that has been tested and approved to contain electrical components. Although the joints of EX enclosures will permit the entry of explosive vapors, an explosion proof enclosure’s main objective is to contain any explosion that occurs within itself. After an internal explosion, the gas travels out of the enclosure through the threaded joint. The gas cools off as exits, so it will not ignite the volatile surrounding atmosphere, thereby preventing potential catastrophic damage, injury or even death.

There are a few important highlights when talking about EX enclosures:

Flame Paths

- This is considered the path that is used to prevent any explosion or spark from the interior of the enclosure to the exterior. UL 1203 Standard states a flame path is the joint formed upon assembly of parts that are intended to arrest the flame and vent hot gases produced when an ignition of an explosive atmosphere takes place within an explosion-proof enclosure.

- There are a few different types of flame paths:

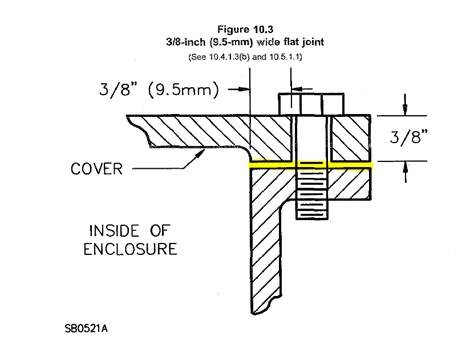

- Flat joint is considered to be continuous without interruption of an O-ring groove or the like.

- Shaft openings (non-rotating) have a specific and finer tolerance than shafts that are rotating. The importance is that the shaft is centered within the hole it is placed through, resulting in a consistent flame path clearance around the entire diameter.

- Shaft openings (rotating) are required to have a ball bearing or sleeve bearing to ensure the shaft rotates about its true axis during operation. These paths have different tolerance requirements than non-rotating due to the addition of bearings which typically create a tighter path during assembly.

- Threaded paths require five minimum threads for NPT type threads and vary based on standard fastener threads. This helps ensure the fasteners are secure and provide a means for a flame or spark to not propagate from the interior of the enclosure.

- These paths/surfaces must be kept clean from debris and scratch or physical flaws. Any damage or debris present may increase or alter the flame path, thereby creating a path greater than what is deemed safe by UL 583 standards. The tolerance of these surfaces is very crucial. A small piece of paper, or even dust on a lid flange, may shim the lid surface off the mating surface beyond what is safe for the environment which may lead to a spark or flame leaving the enclosure. See figure 10.3 from UL 1203 below.

- RICO Service Tips:

- When working with these flame paths, it is important to first tape off the surface to protect it from potential scratches, dust and debris, or physical damage.

- Then, prior to install, wipe the surface with a mild cleaning solution to ensure no debris is present.

- Instructions for taping off the enclosure is explained and demonstrated in our technical support video series: Tech2Tech.

Lid/Mating Surfaces

Lid/Mating Surfaces

- Any component that must be fastened down is required to be torqued to the specific fastener’s dry torque rating. It is crucial that the fasteners are threaded properly and are not stripped during fastening. Any stripping of the fastener threads will critically damage the flame path, potentially resulting in catastrophic failure of the enclosure to cool the gases before reaching the exterior. Fastener torque specifications can typically be found in your operator manual.

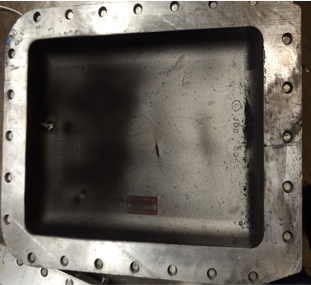

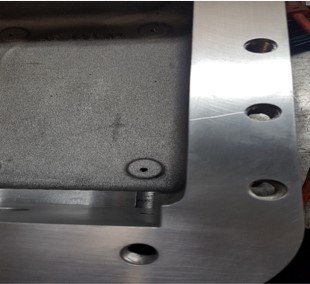

- The enclosure and lid are mated together. If one becomes damaged, the entire enclosure and lid must be replaced. As stated before, these paths/surfaces must be kept clean from debris scratches or physical flaws. Below you will see two surfaces:

- The image on the left is obviously corroded and damaged.

- The image on the right may look clean at first glance, but even the smallest scratch creates the potential for a disastrous explosion.

Wiring

- All wiring entering EX enclosures have threaded connections that thread deeper than typical threads used. This is to help prevent the threaded connection from loosening during operation to a point that is unsafe or may result in the wiring removing from the enclosure.

- Any exposed wiring not in a conduit must be Intrinsically Safe (IS) wiring. The conduit can be metal or encased wireway, such as MI cables.

- Wiring conduits are required to be sealed from each connecting enclosure. This must be done using an EX-rated sealing epoxy. This seal prevents an explosion from travelling between enclosures via the conduit.

- Note: No additional wiring or components can be added without the approval of RICO, otherwise the vehicle is no longer EX-Rated.

Lights/Options

- EX enclosures aren’t limited to steel boxes like pictured above. All lights on the vehicle are required to be either EX-rated or contained in an EX -rated enclosure. For example, the lights we use are placed in an enclosure.

- Note: No additional options are able to be installed on the vehicle without approval from RICO, otherwise the vehicle is no longer EX Rated.

When attending our EX University program, you will have the opportunity to see a test demonstration of an explosion proof enclosure properly working, as well as what happens when it does not contain an explosion. Only EX trained technicians should perform maintenance and repairs to maintain proper compliance for this equipment, so be sure to schedule a training for you and your team today!

For additional information on EX components, schedule a training, or to request a quote, be sure to contact us to speak with one of our experts!