Custom Material Handling

Equipment and Vehicles

RICO Manufacturing offers a wide range of custom built, engineered models. Whether you're in need of an explosion proof vehicle or a narrow aisle lift truck, our team will engineer the vehicle to meet the needs of your environment.

Explosion Proof

RICO’s standard for excellence in design, manufacturing and installation of trucks instills in us a responsibility to create the best EX-rated lift trucks on the market today. Simple maintenance, clear operator visibility, and outstanding parts and service support are always tied to the creation of our trucks. What is critical in the manufacturing process are steps we take to insure safety in our vehicles. All of RICO EX trucks are built to the UL 583 specifications and are approved by the Nationally Recognized Testing Laboratory (NRTL). Our EX-rated trucks are available in various models and configurations, as presented throughout. From pallet and counter balanced trucks to straddle, reach, platform and tractor, our exacting specifications and adherence to all safety levels are what you have come to expect from RICO custom material handling equipment.

Pegasus Counterbalance

RICO Manufacturing has redefined material handling yet again with the PEGASUS COUNTERBALANCE. Pegasus ELITE design is based on RICO’s original Pegasus Series foundation but in a STANDARD chassis and standard, industrial certified components. The all-steel frame offers multiple mast and fork combinations to service various markets that have load capacities ranging from 18,000 to 80,000 lbs. The team at RICO, using our vast knowledge and extensive resources in the material handling industry has built the Pegasus with performance, safety and quick delivery in mind. Comes in Pegasus ELITE (standard) and Pegasus SP-Series (specialty). When you need the pinnacle of heavy duty material handling, expertly crafted with unparalleled precision and reliability, think RICO.

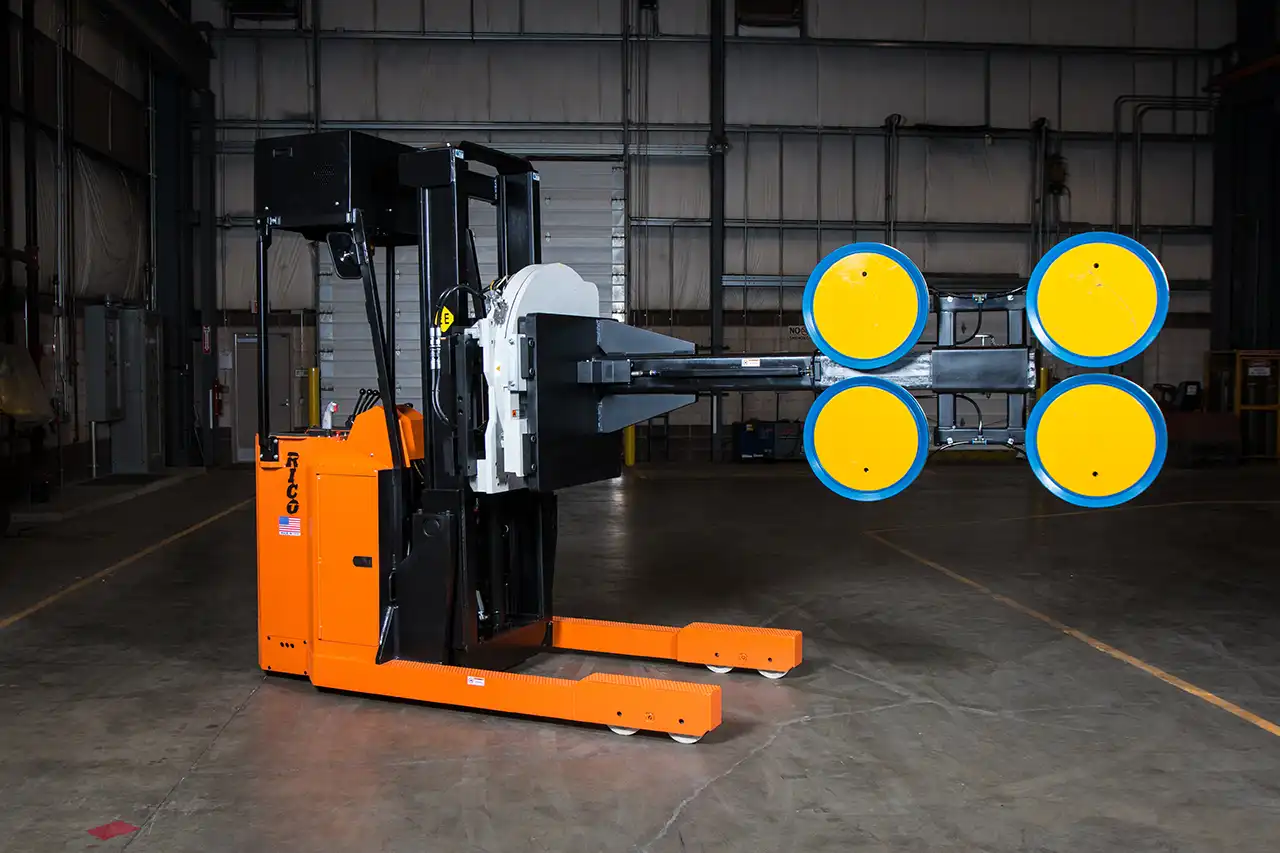

Quick Die & Mold Change

For die change efficiency and precise positioning of dies to press, these trucks feature an individually or tandem controlled push/pull mechanism. To maximize truck to press efficiencies, we have optimized both sight and maneuverability through our clear view masts and tighter turning radius design. The QDC’s “V” docking system, with either hydraulic or mechanical docking capabilities, provide consistent and secure alignment of the die truck to presses and storage station. Integrated with our Fiber-Optic camera system, operators perform this docking operation with greater visibility, confidence, and efficiency which effectively eliminates repeated truck repositioning to press, providing a rapid return on investment.

Specialty Vehicles

When the application is unique – you need a company capable of out-of-the ordinary solutions you need a team of experts to understand and develop a solution for your toughest challenges. You need innovative solutions in material handling.