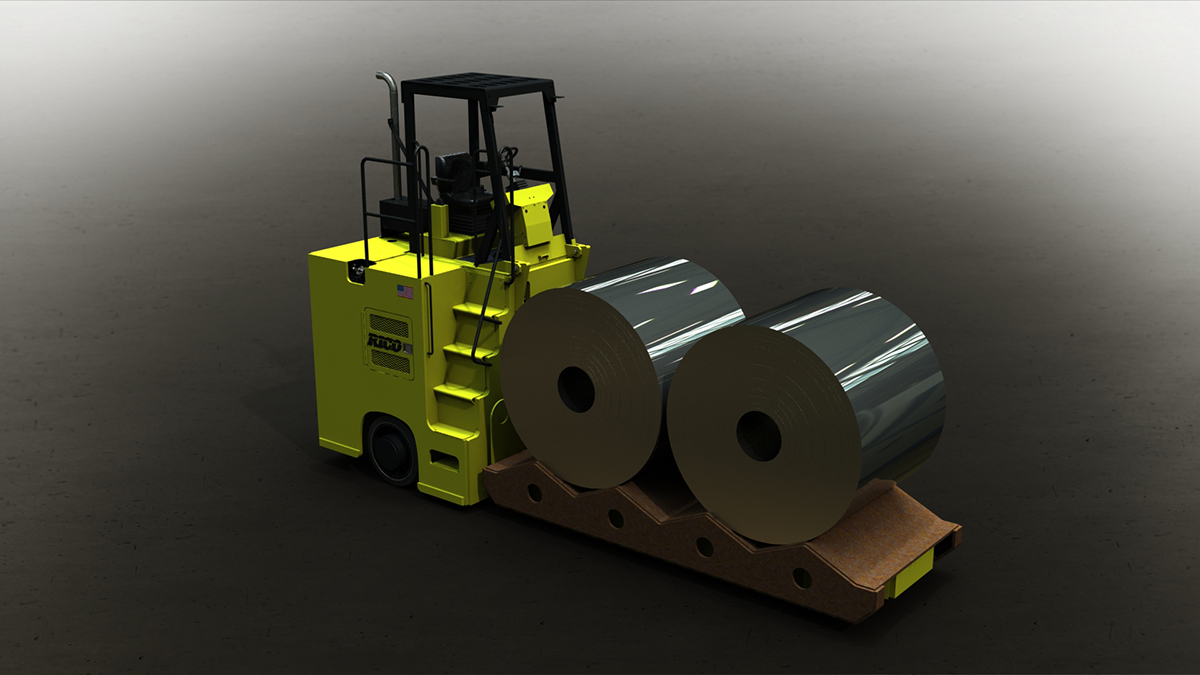

A sheet metal provider for the automotive industry uses sit-down rider platform truck to transport 90,000 lb. skids and rolls over long distances

Industry Showcased: Steel & Stamping

Capacity 90,000 LBS

Solution:

This vehicle provided a solution for handling high capacity loads safety and securing allowing the operator greater visibility and load control.

Product Highlights:

This sit-down rider platform truck was manufactured for a company which produces sheet metal products for the automotive market. It was designed to handle skids used to transport multiple rolls of aluminum or steel. The combined weight of the skid and rolls is in excess of 70,000 lbs.

Due to long travel distances; the customer wanted a top loaded speed of 6+ mph. This was accomplished by using a 155 HP, tier 4, diesel engine to power our hydrostatic drive system.

The operator’s seat is elevated 8 feet off the ground to provide superb visibility over the tall load. Instead of a straight ladder, a staircase with handrails was provided for safe and easy ingress and egress.

Many maintenance-friendly enhancements have been incorporated into the design of the sit-down rider platform truck. The entire engine assembly pulls out on a tray for accessibility that would make any car mechanic jealous. The cab folds forward allowing quick access to the hydraulics. The fuel and hydraulic reservoirs can be accessed from hinged doors located on either side of the chassis. All pivot joints in the platform complex utilize self-lubricating, PTFE lined sleeve bearings to ensure a long life with minimal maintenance.